|

As drivers, we have all seen old pavement markings showing through at roadwork sites. Temporary Traffic Management often requires that pavement markings are altered or covered up, so what is the most effective way to do this? The photograph below shows how a failure to cover up markings can result in a hazardous site. This is not the only hazard at this site, but I will use it to demonstrate how the pavement marking can be addressed. An obvious solution is to simply cover up the markings with black tape or paint. I’ve seen workers racing off to Bunnings when I raise this issue – alas, it’s not that simple. Section 6.6 (Pavement Marking) of Austroads Guide to Temporary Traffic Management Part 3 states “markings must not be covered using black or grey paint as under certain light or wet weather conditions they may appear indistinguishable from white markings”. It also states that “for shorter term worksites, temporary tape/ stickers may be used to cover line marking or other pavement marking (e.g., turning arrows)”. I’m not on the payroll for 3M and I don’t have a commercial arrangement with them, but they do provide a very good covering tape they call ‘Stamark™ Removable Black Line Mask 715’. If there are any other providers out there that provide a good covering tape, feel free to add your details in the reply section of this post. Regardless of the tape used, covering a marking in the same shape as the marking will result in this showing up in various weather conditions, sometimes better than the required markings. Whilst it’s easy to tape over a pavement arrow with a rectangular box of tape, the same cannot be done for line markings. In these instances, cross sections of tape can be used to make it clear that this is an old marking, as shown in the example below. The top picture represents the black tape in regular conditions whilst the bottom picture show how this would look if sun glare and or wet conditions make it appear white again. Now that we know how to address the issue of old markings showing through, how do we ensure that the tape stays in place? Like just about everything else in life, we need to read the manufacturers’ instructions and follow them to the letter. 3M indicates that if you do, their tape will last for up to 12 months. This is how they say their product should be installed:

“Ideally you want to clean any debris from the road to have a clean surface to adhere to. No need for anything dramatic, a truck blowing pressurised air (or a leaf blower for smaller sections) will do just fine. You can then either roll out the tape in a single line and cover the existing markings (for long lines) or cut-out to shape and apply over other types of markings (e.g., arrows etc.) The next step is one of the most important ones for proper adhesion for the duration of the project and I always try to emphasise it to the application crews – Tamping! Once you apply the Stamark tape on the road you need to apply pressure on (tamp) to activate the adhesive. You can either use a foldable weight cart that we can provide (minimum of 90kg) or use the wheels of a vehicle to drive over (typically best for long lines). The tape needs to be tamped at least 3 times each way (6 times total). Once you finish with the tamping you can open the road to traffic immediately (or move on to the next job on the site). At the end of the project, when the crew are ready reopen the road with the original markings, all they have to do it pull the Stamark tape up (90-120 degrees), at a relatively slow rate (walking). The tape has a built-in net to assist with coming off in single or large pieces for quick removal with minimal to no bits left behind. The tape at this stage cannot be recycled in case you are wondering, so once pulled up it will need to be disposed of at the land fill.” Disclaimer This article is made available by the author for educational purposes only. It provides general information. This article should not be used as a substitute for seeking professional advice for your own application.

0 Comments

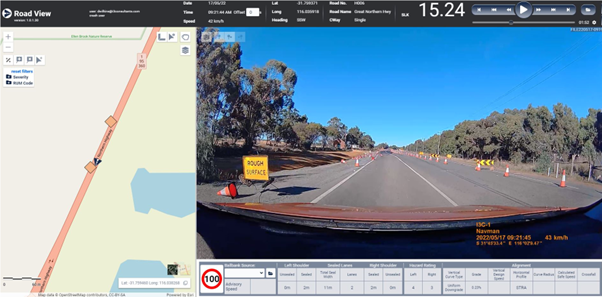

Way back in February 2019 I published an article identifying the 10 most common reasons for ‘failure’ I found when undertaking Compliance Audits or Inspections of Temporary Traffic Management Schemes for roadworks. A lot has happened since then, including the adoption of the Austroads Guides to Temporary Traffic Management (AGTTM) and unfortunately, a number of serious injuries and deaths within roadwork sites. At the time of publication of my 2019 article, I had undertaken 37 Roadwork Traffic Management Audits or Inspections and noted that only one of these had passed with flying colours. Since then, I have undertaken a further 138 audits or inspections of roadwork sites. Unfortunately, once again, only one of these sites passed with flying colours. What do I mean when I say passed with flying colours? It’s quite simple. It means that the site was set up exactly as per the approved Traffic Guidance Schemes(TGSs) taking into account the permitted variances in sign spacings and the inclusion of approved variations. It’s not difficult, so why doesn’t it happen? I suspect it might be the tender process that awards work to those who can do it using the least amount of resources or the belief of a few traffic management personnel that they know how to manage traffic on-site better than the instructions they have received via the approved TMP and TGSs. Or it may just be that the personnel on site have not been provided with the approved TMP or the correct number of devices to set it up. Whatever the reasons, the fact remains that the vast majority of traffic management sites that I have inspected do not comply with the approved TMP and TGS. Some in the industry have suggested that if they knew what the key failures were, this would assist in addressing the issue, so here goes: 1 Site not set-up as per the approved TGS.This requires you to have the correct type and number of signs and devices on site (refer Issue 2). The designer of the TGS is required to have inspected the site beforehand (refer Issue 3) so there should not be a problem installing the signs and devices due to road safety barriers, embankments, paths, or trees. If there is a problem, then a variation should be sought, approved, and included in the Daily Diary. 2 No list of required signs and devices on TGS or in TMP.Section 3.4.1 (Plan and design selected risk treatment) and Section 4.7.3 of AGTTM02 (Traffic Management Planning) requires that each TGS “includes an itemised list of all required signs and devices, including type, size and quantity of devices”. The use of an itemised list of signs and devices should ensure that the correct number, size and type of signs and devices (including sign legs and sign coverings) are available and used on site to permit the site to be set up as per the approved TGS. 3 The designer of the TGS has not inspected the site.Section 3.2.1 AGTTM02 requires the designer of the TGS to inspect the site at least once prior to preparation of the TMP and TGSs. As such, each TGS should show all existing signs along with notes indicating whether or not they are to be retained, removed, or covered. If the TGSs do not show these, and instead rely on an overall comment to the effect that existing signs that conflict with the temporary traffic management signs shall be covered, it’s highly likely that the inspection was not undertaken in accordance with the guidance provided in AGTTM02. Main Roads WA has recently developed an application called Road View that allows designers to drive through the site with dash cams and then view the video and associated GPS files in Road View along with relevant road data and SLKs, as shown in the example below. Auditors such as myself make use of this tool during the audits and inspections and there is no reason why designers of the TMP cannot also use this tool to ensure that signs can be placed where they will be visible at all times. 4 Risk Assessment.It’s interesting that designers accept that no two roadwork sites are the same, but they keep pasting the same old risk assessment table in the TMP. Yes, we need to include ‘generic risks’ but we also need to include risks that are unique to the TMP and unique to each TGS. Quite a few designers are including two risk tables in the TMP, one for generic risks and the other for site specific risks. Fantastic. However, many of the risks have identified treatments that are not in the TMP and/ or TGSs. If the remedial treatment is not included then the initial risk remains and quite often this places the entire project in the “Unacceptable risk. HOLD POINT. Work cannot proceed until risk has been reduced” category. The solution? Add another column to the right of the Risk Table with a ‘TMP Ref’ heading. That way you can check and ensure that each remedial treatment is clearly communicated in the TMP or TGS. And most importantly, don’t forget to include the risk associated with the decision to work close to traffic instead of simply closing the road and detouring traffic around the site. 5 Variations. It is rare to have a ‘standard worksite.’ I get this and so does Main Roads WA. Both the Code of Practice and the Standard allow for Variations. The front cover of the TMP Template uses bold text to highlight this in its Declaration, i.e.: If your TMP and/ or TGSs contain anything that does not comply with the requirements of the Code of Practice, AGTTM or Standard then you must follow the directions in Section 4.5 of the Code of Practice. If you don’t, then the TMP does not comply and should never have been signed or approved and all those that signed it or approved it are placing their accreditation at risk as well as themselves should there be an event resulting in coronial or legal procedures. It is quite common to observe variations on site to those on the approved TMP and TGSs and there are often good reasons for this. There are also procedures within the Code of Practice to accommodate this. Basically, if there are differences on site to that in the TMP and the TGSs there are two options:

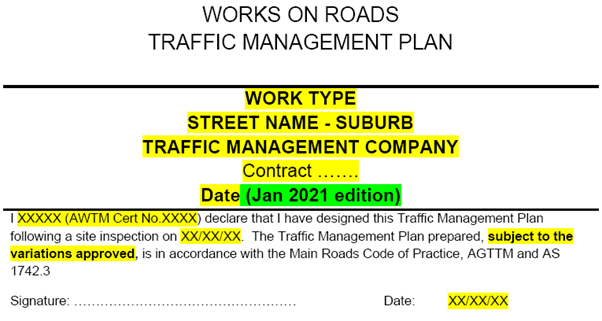

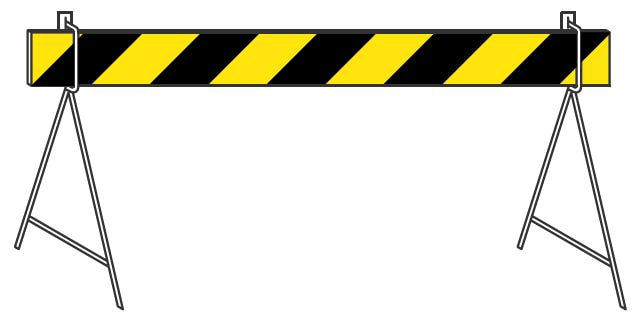

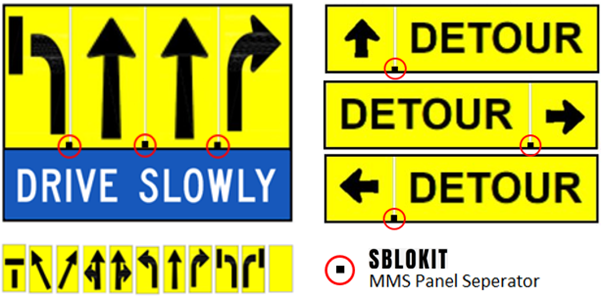

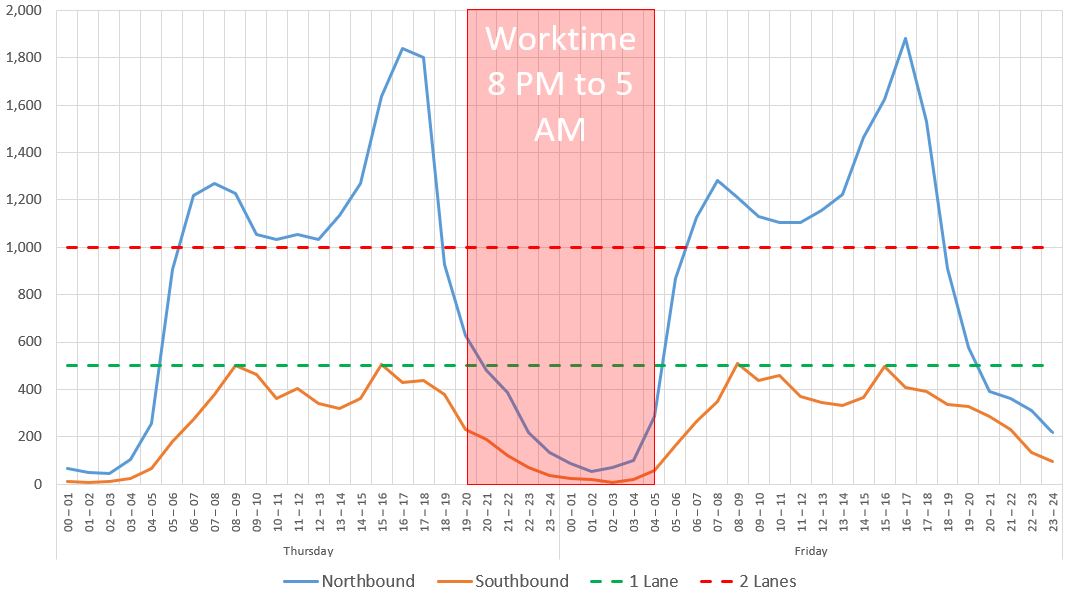

Designers should be aware that traffic management personnel on-site have a particularly good understanding of how drivers are reacting to, and behaving within, the roadworks site. Visiting the site and talking to personnel after implementation will allow designers to continuously improve roadwork sites as well as stimulate changes in the requirements of the Code of Practice through the Main Roads Traffic Management for Works on Roads Advisory Group, as occurs on a regular basis. 6 Excavations not shown or managed in the TMP and TGS. There seems to be a misconception that an excavation less than 250 mm deep is not a hazard. Let’s debunk this myth. Section 6.8 of AGTTM03-21 defines an excavation as “a longitudinal depression with a side slope of 1.5 horizontal to 1 vertical or steeper adjacent to traffic.” Excavations are deemed to be particularly hazardous when they are readily accessible to any person, likely to collect or retain water of such a depth as to constitute a danger or are left unattended. In these instances, AGTTM03-21 requires that they are fully covered, fenced, or backfilled when left unattended or protected by road safety barriers. Most construction activities on roads include excavations, e.g., boxing out and drainage or service works. The failure to include identification of these excavations, risk assessment and control methods constitutes a significant failure in the design of the TMP and TGSs. 7 Barrier boards not used at road closures Clause 4.10.1 (Signs) of AS 1742.3-19 states “The ROAD CLOSED sign shall be used where a roadway is closed to traffic. Barrier boards completely barring access to the roadway shall be used in conjunction with the sign.” 8 Assess traffic volumes and queue length. In recent years, a number of incidents have occurred at roadwork sites with end of queue collisions. Many of these have resulted in fatalities and serious injuries due to them occurring on high-speed rural highways. To avoid these types of incidents occurring, it is imperative that the calculation of predicted end of queue lengths is as robust as possible as moving the required warning signs during the works to reflect substantially different queue lengths involves additional risk for traffic management personnel. In WA, the Code of Practice and Standard provide clear guidance on acceptable traffic volumes per lane per hour for both mid-block and intersection roadwork sites as well as the method for calculating end-of-queue lengths. Main Roads WA provides easy access to traffic volume and traffic signal (SCATS) data on their online Traffic Map. Instead of copying this data and pasting it into the document, the designer of the TMP needs to show an assessment of the data and the implications of this at various times of the day. This allows for workers on site to have a clear indication of whether or not they can extend the time if this is required to finish works on a particular day. 9 Panels within MMS obscured due to slippage. The sign panels within an MMS have been observed to slip behind other panels resulting in partial obscurity of the required sign. Section 6.2.3 of the Main Roads WA Code of Practice attempts to address this issue by requiring that ‘there shall be at least two (2) 5 mm thick core flute signs back-to-back in the multi-message frame to help prevent the sign from sliding across’ whenever signs are left unattended. Inserting additional panels in the MMS behind the required panels has not always addressed sign slippage, as shown below. As a Roadworks Traffic Manager that regularly audits and inspects roadwork sites, I knew there must be a simpler and cheaper way of addressing the sign slippage problem. As a result of this, I developed and trialled a simple device called a SBLOKIT (Sign Blocker) that has been approved by Main Roads WA for use across the road network in Western Australia. Furthermore, as it is clear that non-compliance is more likely to occur when service providers attempt to save costs, care was also undertaken to ensure that SBLOKIT reduces operating costs compared to the current approved method, providing a robust method for enhancing road safety and allowing providers to allocate cost-critical resources in a more efficient manner. More details regarding this device can be found at https://leglesssigns.com.au/. 10 ‘Handmade’ signs. The use of handmade signs on-site demonstrates a failure to adequately plan and prepare for the works. The list of required signs and devices (refer Issue 2) should clearly identify the need for special signs to be prepared prior to going out on site and setting it up. Section 2.5.3 of AGTTM03-21 clearly states, “Sign messages must not be permitted to be formed with tape, for example, Lane Status signs and mocking speed numerals in tape”. PESDESTRIAN and DETOUR direction sign panels are also often observed to have been modified on site, usually because the panel with the arrow in the required direction is not available. The recent approval by Main Roads WA to use a SBLOKIT to prevent signs from moving within an MMS frame allows for the correct Lane Status and PEDESTRIAN and DETOUR direction signs to be provided on site using a combination of panels, as shown below. Once again, more details regarding the SBLOKIT device can be found at https://leglesssigns.com.au/.

Additionally, if have any questions about SBLOKIT or how it can be integrated into your workflow then you can also reach me via email at [email protected]. First of all you need to allow 1.0 m for the 'cyclist envelope'. The minimum width between the 'cyclist envelope' and passing trucks is then 1 m for 60 km/h, 1.5 m for 70 km/h, 1.5 m for 80 km/h and 2.0 m for 100 km/h.

If you can't fit the logo in then its safe to say it's not right. Pedestrians and cyclists are the most vulnerable road users. We should design for them first and then design for cars and trucks around them, not the other way around. Cycle lane design guidance can be found in Austroads Guide to Road Design Part 3: Geometric Design (2021) and Guide to Road Design Part 6A (2017) - available to download for free from Publications | Austroads. Austroads 'Cycling Aspects of Austroads Guides', 'Australian National Cycling Strategy', 'Low Cost Interventions to Encourage Cycling' and 'Cycling Infrastructure Case Studies' also provide some useful guidance. Pedestrian falls are not recorded in crash data and could be forgotten when undertaking road safety audits. Falls are, however, recorded in Hospital Admissions Data. In Western Australia this data has indicated that:

Looking out for these hazards when undertaking audits and including them in the audit report can help reduce the incidence of falls on our paths and the associated injuries, hospitalisations and fatalities. State and Federal Governments in Australia have fast-tracked major infrastructure projects to support jobs during COVID-19.

Unfortunately, I am not aware of any changes to the requirements for road safety audit teams, or site visit protocols, to enable Road Safety Audits to be undertaken in a different manner to that prescribed by the relevant road safety audit administrators in each State and Territory. I first raised this issue with the WA Road Safety Audit Panel on 23 March 2020, with a reminder on 6 April. There has not been any change to the process in this time. It is important that the Road Safety Audit process continues as this will allow for audits to be undertaken for the fast-tracked major infrastructure projects. It is also important that the Audits are undertaken in a safe manner. In recognition of the above, I recommend the following: Site Visit Changes Auditors are currently required to visit the site for all road safety audit stages, i.e. Stage 1: Feasibility, Stage 2: Preliminary Design, Stage 3: Detailed Design, Stage 4: Pre-opening and Stage 5: Roadworks. I recommend that the requirement for a physical site inspection is removed for Stage 1 and 2 audits, except for those circumstances where the Audit Team Leader has determined that it is critical. The Audit Team can use on-line aerial and satellite photographs and software to assist with Stage 1 and 2 Audits. I also recommend that the requirement for the Audit Team to visit the site for Stages 3, 4 and 5, is relaxed to allow for the Audit Team Leader to visit the site and provide the audit team members with Dash-cam video when driving, body-cam video when walking or riding and GPS coded photographs taken during the site visit. The video should include narrative from the Audit Team Leader. Where it is deemed essential for an Audit Team to inspect the site, the team should be limited to the Audit Team Leader (an accredited Senior Auditor) and an accredited Auditor. Key Personnel All Senior Road Safety Auditors should be classified as “Specialist required for Industry” and permitted to travel to and from sites on this basis. Request the change I urge all Road Safety Auditors to contact the relevant authorities in their Sate or Territory, or local member of Parliament, to get these changes through as soon as possible so that we can continue to work together to provide a safer road network. Audit Team Leader on 14 Road Safety Audits (3 Preliminary Design, 5 Detailed Design, 1 Roadwork and 5 Pre-opening) on the Great Northern Highway Muchea to Wubin Upgrade Program: New Norcia, Miling Straight and Miling Bypass Packages | Main Roads, Jacobs and Arup.

Main Roads WA established an Integrated Project Team with Jacobs and Arup for the planning, development, design, construction procurement and construction management of the Great Northern Highway, Muchea to Wubin Stage 2 Upgrade Project. Comprising seven procurement packages over a 218 km regional road north of Perth, the program has improved road safety, increase freight efficiency, contribute to sustainable communities and enhance the environment. Through the three completed packages, this has proven to be an extraordinarily versatile project management instrument for managing the development and delivery of an optimised rural road upgrade program.

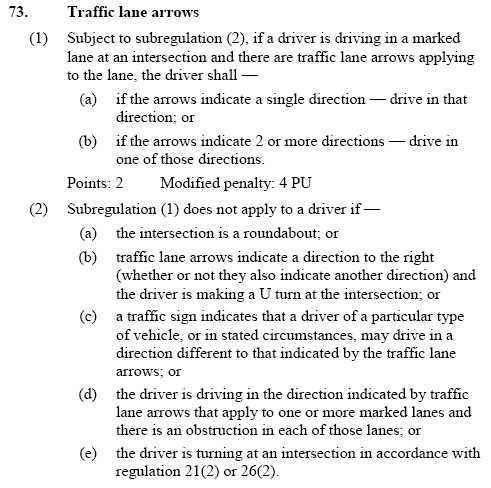

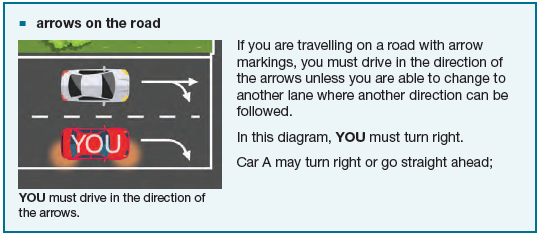

Can you turn left or right when the Traffic Controller turns the bat from STOP to SLOW at this Road Works site in WA? (The signals are on flashing amber). Road Traffic Code 2000Regulation 73 (Traffic lane arrows) of version 05-10-02 of the Road Traffic Code 2000 states: Note that Subregulation 1 does not apply if “the driver is driving in the direction indicated by traffic lane arrows that apply to one or more marked lanes and there is an obstruction in each of these lanes.” The definition of an “obstruction” in the Road Traffic Code 2000 is “includes a traffic hazard but does not include a vehicle only because the vehicle is stopped in traffic or is travelling more slowly than other vehicles”. Despite not specifically mentioning road works in the “obstruction” definition, Regulations 22(3), 26(3) and 59(2b) identify “roadworks” as an example of an obstruction within a lane. Based on the above, it appears that the Road Traffic Code 2000 allows for right and left turns to be made legally from the straight-ahead lane on the basis that these turn lanes are provided on this approach but are “obstructed”. Drive Safe HandbookThe introduction to the Drive Safe Handbook indicates that: This handbook is a comprehensive guide to the road rules that apply in Western Australia. It is written in an easy to understand format and designed primarily to help new drivers prepare for a lifetime of safe driving. If you are a new driver, this book contains the information you will need to obtain your learner’s permit. The laws explained in this book are the major ones that are contained in the Road Traffic Code 2000 and Road Traffic (Vehicles) Regulations 2014. However, drivers should be familiar with all traffic laws and a copy of the relevant rules and regulations can be viewed on the internet at www.slp.wa.gov.au or purchased from the State Law Publisher. The following diagram within the Drive Safe Handbook indicates that drivers must drive in the direction of the arrows. Australian StandardsClause 5.5.2.3 (Intersection arrows) of AS 1742.2-2009 states “Intersection pavement arrows give a positive indication of the paths vehicles must follow at intersections or roundabouts. They are legally enforceable.” Clause 2.3.2 (Safety and convenience) of AS 1742.3-2009 states “When they are not applicable during the works period, regulatory signs shall be removed or covered. Regulatory pavement markings likewise shall be either obliterated or traffic control measures employed to direct traffic along paths which might otherwise infringe the regulatory requirements of the markings. Coroner's FindingsAt the Inquest into the death of Peter John Bonnell [2018] NTLC 002, the Coroner made a Finding (#23) that: “If existing markings are not appropriate or are potentially misleading, they should be removed and replaced by more suitable markings …” SummaryIn summary, it appears that it is legally permissible to turn right, left or travel straight ahead from a lane with pavement arrows indicating only other movements are allowed provided that the other lanes on the same approach indicate that these movements are permissible but are obstructed (closed) by roadworks. This assessment has indicated that it is unlikely that drivers will be aware of the ability to perform the movements indicated above as this is not clearly indicated in the Drive Safe Handbook. The Australian Standards indicate that pavement markings should be obliterated or managed within road work sites and a Coroner has indicated that if existing markings are not appropriate or are potentially misleading, they should be removed and replaced by more suitable markings. Roadworks are complex sites and signs should mean what they say to avoid any confusion or ambiguity. ActionThis assessment will be raised and discussed by the author with Main Roads WA through the Traffic Management for Works on Roads Users Group to identify and agree a consistent and clear method of addressing the issue of pavement markings within roadwork sites.

Lessons learned from Roadwork Traffic Management Audits and Inspections (Top 10 Reasons for Failure)1/3/2019

The stated purpose of roadworks traffic management is to protect road users and workers on-site. But there is another group of people that require protection of a different kind, and that is the people who design, administer, supervise, audit, inspect and implement roadwork traffic management schemes. A coroner recently reported that it was obvious the setup of the roadwork traffic management site at a fatal crash site in Darwin was unsafe and that offences had been committed under the Work Health and Safety Act that required reporting to the Commissioner of Police and the Director of Public Prosecutions. More details regarding this coronial finding, including a link to the report, can be found here. If you have read this coronial report, work in the Industry and can honestly say that you have never seen or been involved in any similar roadwork traffic management scheme in WA then read no further. Still here? Let’s get started. Roadwork Traffic Management is not rocket science, but it does require one thing in common with rocket science and that is ATTENTION TO DETAIL. You know it’s important when it’s in shouty capitals, bold text and underlined. Everything you need to know about preparing, implementing and administrating roadwork traffic management sites in WA is covered in the following two documents:

To keep things simple, I will refer to these as the Code of Practice and the Standard. Yes, there is a different Code of Practice for Events on Roads, but I will concentrate on roadwork sites in this article. As if the above two documents are not enough to help and guide you, there is also an incredibly helpful Main Roads WA Temporary Traffic Management web-page with everything you need to know, including links to the Code of Practice, templates for preparing Traffic Management Plans, generic Traffic Guidance Schemes and a whole lot more. Most of us know all this, so why am I writing this article? Because I, like many others in the industry and many road users, still see roadwork traffic management schemes on our roads that are clearly wrong and often dangerous. As a Roadworks Traffic Manager (RTM) I have recently undertaken 37 Roadwork Traffic Management Audits or Checks of roadwork sites and only one of these passed with flying colours. Auditing is a thankless task and auditors can be as popular as health and safety personnel. We are seen as trying to find all the things that are wrong and never reporting what is right. Fair enough. But auditors are required to follow checklists. This means that something either complies or does not. There are no fifty shades of grey in roadwork audits. If it complies it gets a tick and no more mention. If it does not comply then we have to report why and make recommendations for compliance. The positive is that auditing is a useful process for identifying things that keep going wrong and providing an opportunity to address these. Hence this article. It’s based on the top 10 common features of those 36 roadwork traffic management audits that did not pass with flying colours… 1 Poor Document Control It’s not hard. You write a TMP and you give it a number. Whenever you change the TMP you add a revision number. That way you will never have any problems with auditors or workers on site using different versions of the TMP. The same applies to Traffic Guidance Schemes (TGSs) that were previously referred to as Traffic Control Diagrams (TCDs). Have a copy of the latest approved TMP and TGSs available on request and on-site at all times. The first thing I ask for when I’m undertaking an audit or inspection is a copy of the latest approved TMP and the TGSs that will be in place when I visit the site. Its also the first thing I ask for when I arrive on-site. I often don’t receive this, or I’m given the wrong version. Whilst it might seem clever for organisations to respond to audit reports with the simple comment that the wrong TMP or TGS was audited, what it really says is that the organisation has very poor records and document control procedures in place and is unable to demonstrate that any person working on-site can obtain a copy of the correct TMP when required. The TMP contains important Health and Safety procedures and requirements, so good luck with explaining that to the Coroner, particularly when all the other audit comments identify widespread non-compliance issues irrespective of which version is used. 2 Approvals, Signatures and Dates Once again, it’s not hard. You are required to use the MRWA template and this has a table on the cover page to include all signatures and details of all approvals obtained. What you may not be aware of is that a signature without a corresponding date for ‘time sensitive’ documents such as TMPs can be invalid, as can ‘picture’ signatures such as JPEG. I have seen signatures with corresponding dates that are prior to the TMP design date and I have seen ‘picture’ signatures of people that subsequently advised me that they had not seen or signed the document. There are a number of electronic document signature, approval and review software products available to address this. If your signature has been scanned for use in documents, make sure you know when it has been used and jump up and down if it is used without your knowledge. Just as important, don’t sign something, or allow your signature to be used on a document you are not happy with. When the smelly stuff hits the oscillating cooling device your signature makes you responsible. The lawyers will say “you signed it so you are responsible” and you will find it difficult to argue against this. A large number of TMPs that I reviewed had the standard “I, [Name] [AWTM XXX-####], declare that I have designed this Traffic Management Plan following a site inspection. The Traffic Management Plan prepared is in accordance with the Main Roads Code of Practice and AS 1742.3.” The TMP was not based on the MRWA template and did not include any Variations. It clearly did not comply with the Code of Practice and to state that it did when it did not, raises significant legal issues. In a nutshell, if in doubt, leave it out. Ask your boss to sign it instead. If they are accredited to do so and refuse, then you have proven to them that changes are required. If they are not accredited to do so, then you have reminded them that you are a better judge of this issue than them because you have been trained in this aspect of the work. 3 Variations It is rare to have a ‘standard worksite’. I get this and so does Main Roads WA. Both the Code of Practice and the Standard allow for Variations. The front cover of the TMP Template uses bold text to highlight this in its Declaration, i.e.: “I XXXXX (AWTM Cert No.XXXX) declare that I have designed this Traffic Management Plan following a site inspection on XX/XX/XX. The Traffic Management Plan prepared, subject to the variations approved, is in accordance with the Main Roads Code of Practice and AS 1742.3.” Once again, it’s quite simple. If your TMP and/ or TGSs contain anything that do not comply with the requirements of the Code of Practice or Standard then you must follow the directions in Section 5.6 of the Code of Practice, i.e. Variation to the Code and Standards. If you don’t, then the TMP does not comply and should never have been signed or approved and all those that signed it or approved it are placing their accreditation at risk as well as themselves should there be an event resulting in coronial or legal procedures. It is quite common to observe variations on site to those on the approved TMP and TGSs and there are often good reasons for this. There are also procedures within the Code of Practice to accommodate this. Basically, if there are differences on site to that in the TMP and the TGSs there are two options:

It is important to remember that if the change is a Variation to the Code of Practice and/ or Standard that it needs to be assessed and approved in accordance with Section 5.6 of the Code of Practice. Designers should be aware that traffic management personnel on-site have a very good understanding of how drivers are reacting to, and behaving within, the roadworks site. Visiting the site and talking to personnel after implementation will allow designers to continuously improve roadwork sites as well as change requirements within the Code of Practice through the Main Roads Traffic Management for Works on Roads Advisory Group. 4 Risk Assessments Please, please, please, stop telling me that digging a hole in the road without any traffic management is very dangerous and requires signs. It’s interesting that designers accept that no two roadwork sites are the same, but they keep pasting the same old risk assessment table in the TMP. Yes, we need to include ‘generic risks’ but we also need to include risks that are unique to the TMP and unique to each TGS. Quite a few designers are including two risk tables in the TMP, one for generic risks and the other for site specific risks. Fantastic, however many of the risks have identified treatments that are not in the TMP and/ or TGSs. If the remedial treatment is not included then the initial risk remains and quite often this places the entire project in the “Unacceptable risk. HOLD POINT. Work cannot proceed until risk has been reduced” category. And once again I become as popular as a camel with diarrhea. The solution? Add another column to the right of the Risk Table with a ‘TMP Ref’ heading. That way you can check and ensure that each remedial treatment is clearly communicated in the TMP or TGS. Hot Tip The Austroads Research Report AP-R403-12 Implementing National Best Practice for Traffic Control at Worksites – Risk Management, Audit and Field Operations is a very good reference document for identifying and managing risks at roadwork sites and includes some very good generic worksite risks and associated consequences and causes in Appendix B. It can be downloaded for free from the Austroads website. 5 Inspect your site yourself before someone else does Main Roads WA requests auditors to provide prior notice of intended audits. I find it very surprising that I am still able to observe and record some very basic non-compliance issues when I undertake the audit. As I mentioned earlier, auditors are required to use checklists and these checklists are freely available on the Main Roads WA Temporary Traffic Management web-page. If you are about to have an audit, why don’t you download the relevant checklist and do one yourself first? You may then become the second perfect worksite on my audit list. 6 Assess traffic volumes (don’t just paste them in the TMP) In addition to Main Roads WA’s road network capacity requirements, there are significant risks associated with congested roadwork sites. Driver’s get frustrated and start ignoring traffic management measures and abusing workers and traffic controllers when delays and queues are excessive. The Code of Practice and Standard provide clear guidance on acceptable traffic volumes per lane per hour for both mid-block and intersection roadwork sites. Main Roads WA provides easy access to traffic volume and traffic signal (SCATS) data on their on-line Traffic Map. Instead of copying this data and pasting it into the document, take the time to copy it into a spreadsheet to allow for easy assessment of appropriate work times. This also allows for workers on site to get a clear indication of whether or not they can extend the time if the works require another hour to finish. I have included an example at the end of this article. 7 Include Temporary Road Safety Barrier details (not just thick lines on TGSs with RSB text) Section 6.5.4 of the Code of Practice is very specific with what is required whenever Temporary Road Safety Barrier Systems are used but very few TMPs include all the required details. Appendix G of the Main Roads Template allows for the relevant details to be recorded. If this is not completed and no similar details are provided elsewhere, then the TMP is non-compliant and should never have been approved or signed off by an RTM. 8 Excavations (a ‘hole’ lot of issues) There seems to be a misconception that an excavation less than 250 mm deep is not a hazard. Let’s debunk this myth. Firstly, an excavation is deemed to have been formed when material is removed by digging as a result of the work, as defined in the Code of Practice. There is a different definition in the Standard, but the Code of Practice takes precedence (Section 1 para 4). Excavations require special consideration to ensure their structural integrity and to minimise the risk of vehicles driving into them and losing control. Section 6.5.1 of the Code of Practice states “As there is an increased risk of motor vehicles driving into excavations during the hours of darkness, where practicable, works should be planned so that the excavations are to be backfilled and compacted by the end of each working day. On sections where excavations cannot be backfilled and compacted, delineation and other requirements shall be provided during the hours of darkness in accordance with Clause 2.4.3 of AS 1742.3 - 2009.” So there you have it. All excavations must be backfilled and compacted by the end of each working day. If this is not possible or practicable, then delineation and other requirements shall be provided during the hours of darkness in accordance with Clause 2.4.3 of the Standard. And don’t forget to also comply with the requirements of Appendix D of the Standard with respect to protection and delineation of all excavations during the day and night. If you know that there will be deep excavations then you need to provide the correct level of protection, e.g. road safety barriers. Placing a note that all excavations will be less than 250 m deep and backfilled at the end of the day when its clear this this will not be the case could get you in a whole lot of trouble. 9 Visit the site (stop relying on Google Earth and Nearmaps and get out on site) The Code of Practice requires a statement on the TMP confirming that a site visit was undertaken by the person who prepared the TMP or another person under his/ her direction, prior to preparing the TMP. The Roadwork Traffic Manager Code of Conduct requires that RTMs make at least one site visit prior to endorsing a Traffic Management Plan. Based on the above, you would think it is impossible to turn up on site and find a different existing road layout than that shown on the TGS, but it happens. It is also common to see signs erected behind trees, bushes, parked cars and other obstacles because the TGS fails to take these obstructions into account when indicating where these signs are to be located. One of the strongest indicators of the lack of a site visit is the lack of existing signs on TGSs. All existing road signs should be shown on the TGS with notes indicating whether they are to be retained, covered up or removed. So get out there. Spend some time getting to know the site and start planning sign locations on site taking into account existing signs and roadside obstructions. 10 Make sure your Hi-Vis clothing, jacket or vest is Highly Visible When is high-vis not high vis? If you don’t want a lawyer to prove that your high-vis is not high-vis after an incident, then I suggest the following:

So that's it. Pay attention to detail, especially the top 10 issues discussed and you will most likely end up with a high quality roadwork traffic management scheme that not only keeps road users and your workers safe, but will also help in protecting your business reputation and viability. David Wilkins is a Main Roads WA accredited Roadworks Traffic Manager and Senior Road safety Auditor with extensive knowledge and experience in the roadwork traffic management industry. He is the WA Engineers Australia Representative on the Main Roads Traffic Management for Works on Roads User Group and an active member of Transport Australia society in promoting the safe system approach to road safety issues. David is the Principal and Senior Road Safety Engineer at i3 consultants WA and works as an expert witness in the field of Roadworks Traffic Management and Road Safety Engineering.

The National Road Safety Strategy is based on the Safe System approach to improving road safety. This involves a holistic view of the road transport system and the interactions among roads and roadsides, travel speeds, vehicles and road users. It is an inclusive approach that caters for all groups using the road system, including drivers, motorcyclists, passengers, pedestrians, cyclists, and commercial and heavy vehicle drivers. Consistent with our long-term road safety vision, it recognises that people will always make mistakes and may have road crashes—but the system should be forgiving and those crashes should not result in death or serious injury. Key inputs to the Safe System are:

The Safe System approach was adopted in Australia during the period of the previous national strategy, through the National Road Safety Action Plans and the strategies of individual states and territories. It is consistent with the approaches adopted by the safest countries in the world, and is a central theme of the landmark OECD report Towards Zero: Ambitious road safety targets and the safe system approach, published in 2008. There are several guiding principles to this approach:

Shared responsibilityWhile individual road users are expected to be responsible for complying with traffic laws and behaving in a safe manner, it can no longer be assumed that the burden of road safety responsibility simply rests with the individual road user. Many organisations—the ‘system managers’—have a primary responsibility to provide a safe operating environment for road users. They include the government and industry organisations that design, build, maintain and regulate roads and vehicles. These and a range of other parties which are involved in the performance of the road transport system and the way roads and roadsides are used, all have responsibility for ensuring that the system is forgiving when people make mistakes.

Road safety responsibilities also extend to various professional groups, as well as the broader community. For example: health professionals have a role in helping their clients to manage their safety on the roads; and parents contribute significantly to the road safety education of their children—not only through their direct supervision of learner drivers, but also by modelling their own driving and road user behaviour. |

AuthorDavid Wilkins, Principal & Senior Traffic Engineer. Archives

August 2023

Categories

All

|

||||||||||||

RSS Feed

RSS Feed